Julian Ellis OBE, M.Phil, C.Text, FTI, MRSC, MAE

Ellis Developments Ltd

Far Close, Rolleston Road, Fiskerton, Southwell, NG25 0UJ, UK

+44 (0) 7976 425899

www.ellisdev.co.uk

Info@ellisdev.co.uk

Ellis Developments Limited

Nottinghamshire, United Kingdom

| Surgical Implants |

| Textile Technology |

| Dt Michelle Rae |

| Julian Ellis Short CV |

| Consultancy |

| Contact Us |

| For sale |

| Shoulder Surgery |

| Vascular Surgery |

| Embroidered Surgical implants |

| Spider-Like Silk |

| Clavicle Replacement |

| Humerus Replacement |

| Nottingham Hood |

| Rotator Cuff Repair |

| Abdominal Aortic Aneurysms |

| Embroidered implant Project Report |

| Implant Picture Gallery |

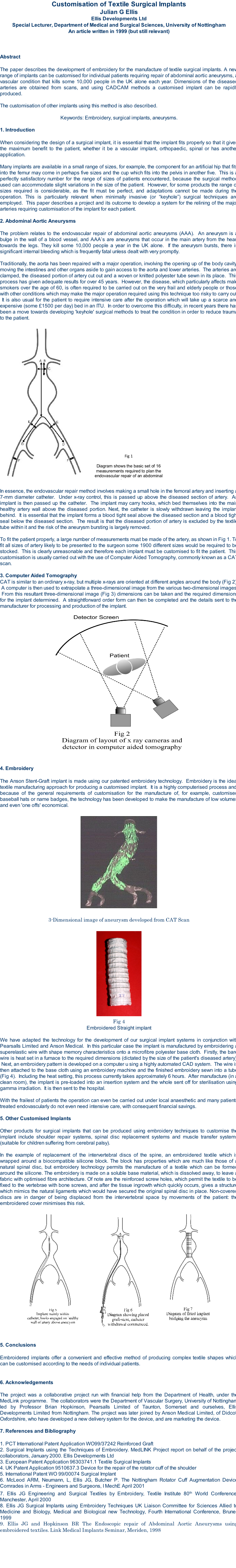

| Customisation of Surgical Implants |

| Embroidery |

| Through Stitching |

| Training and Quality Systems |

| Flammability |

| Composites |

| Engineering Textiles |

| Embroidery |

| Garment Quality |

| Fabric Quality |

| Dimensions |

| Instructors Courses |

| Knitting Operatives Course |

| Warp Knit inspection |

| Double Jersey Knitting Mechanics |

| V Bed Mechanics |

| Z-Axis Stitching |

| Embroidery for Composites |

| Structural Health Monitoring |

| Node and Truss Structures Project |

| Academic Report |

| Embroidery |

| Julian Ellis Full CV |

| About Julian Ellis |

| How to Find Us |

| Embroidered implant Project Report |

| Implant Picture Gallery |

| Customisation of Surgical Implants |